Description

Main Features

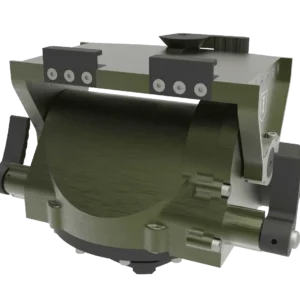

The PED08 provides a combination of controllability, positional accuracy, and price/performance ratio, making it suitable for fixed installations as well as light vehicle applications. It features MIL-STD-461F EMI/EMC compliance, making it suitable for installations across diverse environments, including ground-based and light vehicle-mounted setups.

Distinctive Features

True Servo Drive System: Utilizes brushless motors, enhancing accuracy over stepper motors.

Ultra-Low Power Consumption: Operates at 10W with “Smart Driving Mode” for efficiency.

Active Disturbance Rejection: MCU actively counters external interference for steady operation.

High-Resolution Positioning: 22-bit encoders provide precise positioning and control.

MIL-STD-461F Compliant: EMI/EMC standards ensure resilience in demanding environments.

Tripod Compatibility: Mounts on TMH or TMM tripods for versatile field deployment.

Coastal and Seaborne Customization: Options tailored for marine environments

A. High-Resolution Positioning

B. Compact, Lightweight Design

C. Tripod-Compatible

D. Brushless Servo Motors

Specifications

| PED12 – PX – ABX

Speed/Torque Configuration Breakdown |

||

| PED10 | PX – Pan Axis Speed/Torque Conf. | ABX – Tilt Axis Speed/Torque Conf. |

| Positioner – Electromechanical – Dual Axis | Any “A type” configuration is applicable | Any “A type” or “B type” configuration is applicable |

| Speed/Torque Configuration | A1 | A2 | A3 | A4 | B1 | B2 | |

| Nominal Speed (°/s) | 28 | 48 | 96 | 180 | 28 | 48 | |

| Nominal Torque (Nm) | 185 | 150 | 80 | 60 | 275 | 175 | |

| Peak Torque (Nm) | 225 | 215 | 120 | 100 | 475 | 450 | |

| Momentary Peak Torque (Nm) | 400 | 400 | 360 | 250 | 875 | 875 | |

- Nominal Speed / Nominal Torque represents operation range with %100 duty cycle.

- Peak Torque represent limits for acceleration and deceleration limits.

- Momentary Peak Torque represent limits impulsive shock limits device can absorb.

| Parameters / Configurations | PED12-A2-A1 | PED12-A4-A1 | PED12-A1-B1 | ||||

| Pan – Peak Torque (Nm) | 215 | 100 | 225 | ||||

| Pan –Torque (Nominal) (Nm) | 150 | 60 | 185 | ||||

| Pan – Speed (Nominal) (°/s) | 48 | 180 | 28 | ||||

| Tilt – Peak Torque (Nm) | 225 | 225 | 475 | ||||

| Tilt – Torque (Nominal) (Nm) | 185 | 185 | 275 | ||||

| Tilt – Speed (Nominal) (°/s) | 28 | 28 | 28 | ||||

| Pan – Axis Range (°) | N x 360° | ||||||

| Tilt – Axis Range (°) | Up to ±45° | ||||||

| Resolution (°) | 0.002 | ||||||

| Accuracy (°) | 0.038 | 0.032 | 0.028 | ||||

| Operating Voltage (VDC) | 18-48 | ||||||

| Weight (kg) | 16.1 | 16.1 | 17.5 | ||||

| Communication to the Unit | Ethernet, RS-485, RS422 (Full Duplex), USB | ||||||

| Connector Type | MIL-DTL-38999 | ||||||

| Slipring | Up to 76 lines including (1 Gbit Ethernet, RS422, RS232, HD-SDI) | ||||||

| Stabilization | Available | ||||||

| Dual-Loop Control | Position Control at the Order of 0.001° with Secondary Encoder | ||||||

| Hand Controller | Available | ||||||

| Multiple Payload Interface | Available | ||||||

| Width (A) (mm) | 430 | ||||||

| Height (B) (mm) | 445 (depends on slipring configuration) | ||||||

| Depth (C) (mm) | 270 | ||||||

| Wind Load (km/h) | 120 | ||||||

| IP Rating | IP65 | ||||||

| Temperature (°C) | MIL-STD-810G, Method 502.5 Procedure II – Operational, -32°C

MIL-STD-810G, Method 501.5 Procedure II – Operational, +60°C MIL-STD-810G, Method 501.5 Procedure I – Storage; +70°C MIL-STD-810G, Method 502.5 Procedure I – Storage; -40°C |

||||||

| Low Pressure | MIL-STD-810G, Method 500.5 Procedure I – Storage 37,000ft

MIL-STD-810G, Method 500.5 Procedure I – Operational 10500ft |

||||||

| Vibration | MIL-STD-810G, Method 514.6 Procedure I Category 20, Figure 514.6C-3 | ||||||

| Shock | MIL-STD-810G, Method 516.6 Functional Shock, 20G 11ms, XYZ Axis, 3 Positive and 3 Negative Each Axis | ||||||

| Humidity | MIL-STD-810G, Method 507.5 Procedure I – %90 Noncondensing @60°C, 11 Days | ||||||

| Rain | MIL-STD-810G, Method 506.5 Procedure II | ||||||

| Salt Fog | MIL-STD-810G, Method 509.5, 2 Cycles of 24 Hours | ||||||

| Dust and Sand | MIL-STD-810G, Method 510.5, Procedure I and Procedure II | ||||||

| EMI/EMC Compliancy | CE102 – Conducted Emissions, Power Leads

CS101 – Conducted Susceptibility, Power Leads CS114 – Conducted Susceptibility, Bulk Cable Injection CS115 – Conducted Susceptibility, Bulk Cable Injection CS116 – Conducted Susceptibility, Damped Sinusoidal Transients CS118 – Conducted Susceptibility, Personnel Borne ESD RE102 – Radiated Emissions, Electric Field RS103 – Radiated Susceptibility, Electric Field |

||||||

*Refer to Datasheet

Ordering Information

| Configuration Breakdown | Positioner – Electromechanical – Dual Axis – 12 (Product Class) – Pan Speed/Torque – Tilt Speed/Torque |

| Part Number | PED12-AX-ABX (Check Available Options Below) |

| Available Customizations | Communication Protocol, Output Speed, Output Torque, Number of Slipring Lines, Mechanical Interfaces |

| Combinable Platforms | SEBXX – Multi Channel Thermal Imager

MES10 – Locked Electromechanical Mast Platform MEM10 – Ultra-Stable Electromechanical Mast Platform TMH10 – Heavy Duty Tripod |